Joinery Production

Joinery Production Excellence: Crafting Luxury Interiors with Precision

In the competitive world of luxury interior design, exceptional joinery work separates truly remarkable spaces from merely attractive ones. Antonovich Group has established itself as a leader in bespoke joinery production, combining traditional craftsmanship with cutting-edge manufacturing technology to deliver unparalleled quality in every project.

State-of-the-Art Joinery Manufacturing Facility

Antonovich Group operates one of the most advanced joinery workshops in the region, featuring climate-controlled environments that ensure optimal conditions for timber processing and finishing. The facility houses precision CNC machining centers, automated edge banding equipment, and specialized finishing booths that maintain consistent quality across all production runs.

The workshop's timber storage system maintains strict moisture content controls, with kiln-dried hardwoods and softwoods stored at optimal humidity levels. This meticulous attention to material preparation prevents warping, cracking, and dimensional instability in finished joinery components, ensuring long-lasting durability in completed installations.

Advanced CNC Routing and Precision Machining

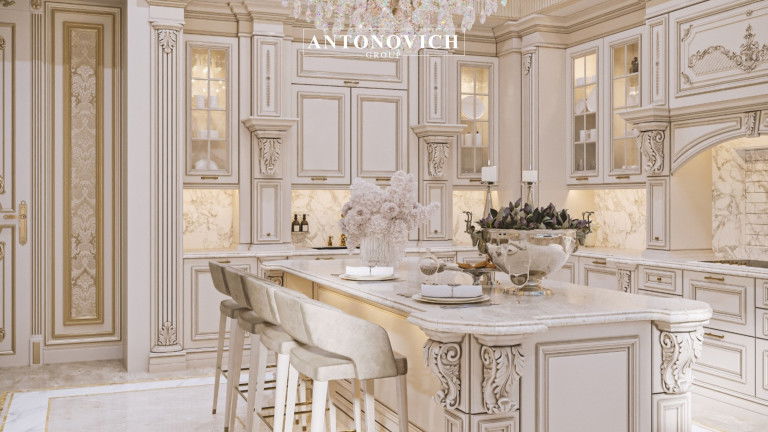

The cornerstone of Antonovich Group's joinery production capabilities lies in their sophisticated CNC routing systems. Multi-axis CNC routers execute complex profiles, intricate carvings, and precision cuts with tolerances measured in fractions of millimeters. This technology enables the production of consistent, high-quality components for large-scale projects while maintaining the detailed craftsmanship expected in luxury applications. Specialized machining operations include spindle molding for custom profiles, pneumatic boring for hardware installation, and automated panel processing for cabinet components. The integration of CAD/CAM software ensures seamless translation from design concepts to finished joinery pieces, reducing production time while maintaining exacting standards.

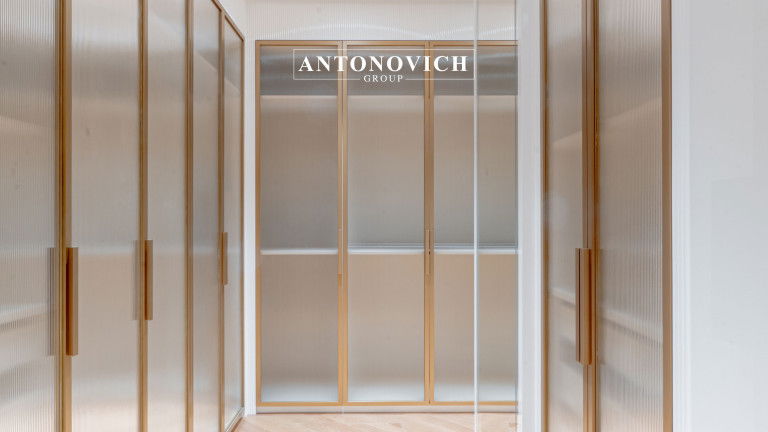

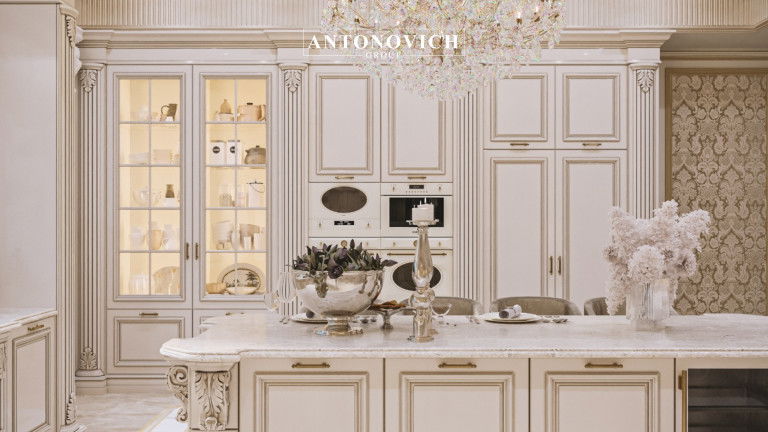

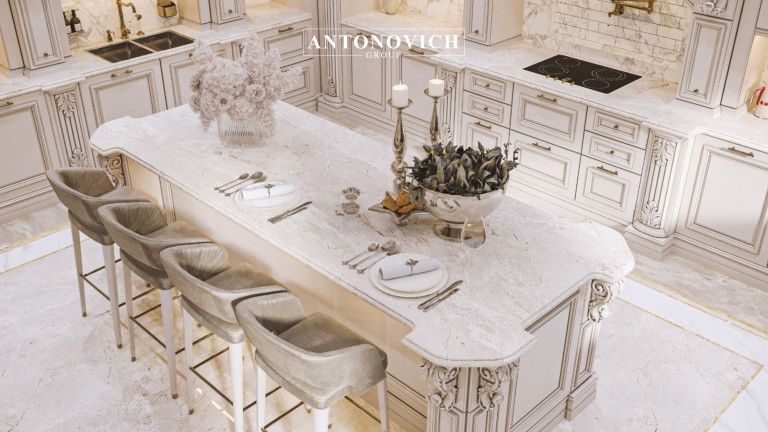

Custom Cabinet Making and Kitchen Joinery

Antonovich Group's cabinet making expertise encompasses the full spectrum of luxury kitchen and storage solutions. Their production processes incorporate premium hardware systems, including soft-close drawer mechanisms, concealed hinges, and precision-engineered drawer slides that ensure smooth operation and longevity. The workshop specializes in various joinery techniques, from traditional dovetail drawer construction to modern mechanical fastening systems. Edge banding operations utilize PUR hotmelt adhesives and laser edge banding technology to achieve seamless joints that are virtually invisible in finished pieces. This attention to detail is particularly crucial in high-gloss and veneer applications where imperfections would be immediately apparent.

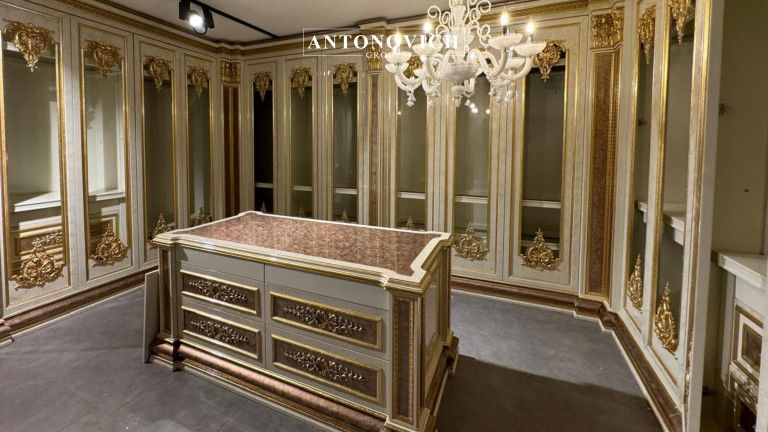

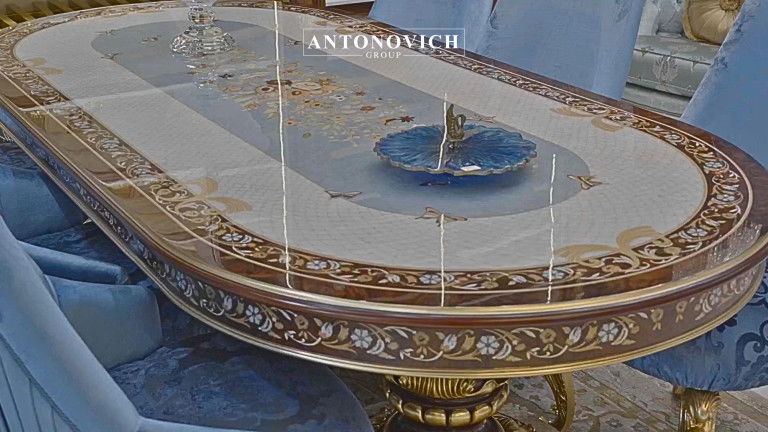

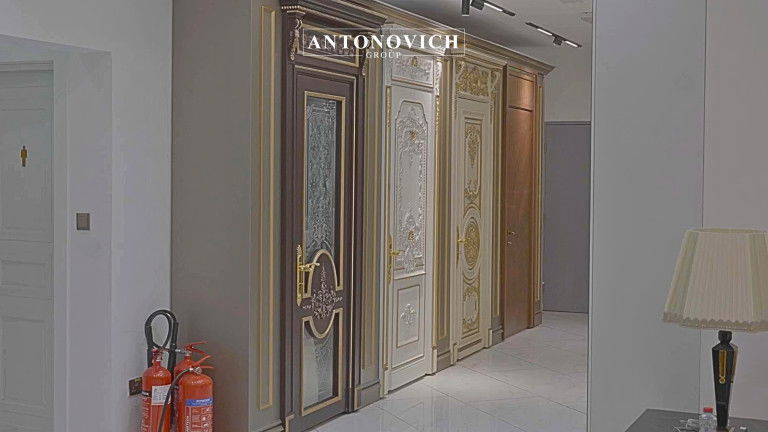

Architectural Millwork and Custom Molding Production

Beyond furniture and cabinetry, Antonovich Group produces extensive architectural millwork for luxury residential and commercial projects. Crown molding, baseboard trim, window casings, and door frames are manufactured using precision profile grinding techniques that can replicate historical patterns or create entirely new designs according to architectural specifications. The company's capability in run molding production allows for consistent profiles across large installations, while their custom millwork services can accommodate unique architectural requirements. Scarf joints, coping cuts, and miter joints are executed with precision to ensure perfect alignment during installation.

Premium Timber Selection and Wood Species Expertise

Material quality forms the foundation of exceptional joinery work. Antonovich Group maintains an extensive inventory of premium hardwoods and exotic species, including European oak, American walnut, cherry, maple, teak, and specialty veneers. Each timber selection undergoes careful evaluation for grain pattern, color consistency, and structural integrity. The workshop's expertise extends to understanding wood movement characteristics, grain direction optimization, and species-specific machining requirements. This knowledge ensures that each joinery component is manufactured from the most appropriate timber selection for its intended application and environmental conditions.

Surface Preparation and Finishing Excellence

Professional finishing operations distinguish Antonovich Group's joinery production from standard manufacturing. Dedicated finishing areas feature controlled environments with proper ventilation and dust filtration systems that ensure contamination-free surface preparation and coating application. The finishing capabilities include traditional oil finishes, polyurethane systems, lacquer applications, and specialty treatments like French polishing for heritage restoration projects. Each finishing process is carefully selected based on the intended use, aesthetic requirements, and durability expectations of the final installation.

Quality Control and Precision Assembly

Rigorous quality control procedures govern every aspect of joinery production. Dimensional accuracy verification, joint tightness inspection, and surface quality assessment ensure that components meet exacting standards before leaving the workshop. Hardware installation is checked for proper alignment and smooth operation, while finish quality undergoes detailed inspection under controlled lighting conditions. Pre-assembly processes in the workshop allow for dry-fitting and adjustment before on-site installation, minimizing field modifications and ensuring precise fit-up. This systematic approach reduces installation time and guarantees professional results in completed projects.

Digital Templating and Precision Measurement

Modern joinery production benefits significantly from digital measurement technologies. Antonovich Group employs laser templating systems and 3D scanning equipment to capture precise dimensional data from existing spaces, particularly valuable in renovation projects where perfect fit-up is crucial. Digital templates feed directly into CNC programming systems, eliminating transcription errors and ensuring accuracy throughout the manufacturing process. This technology is particularly beneficial for complex installations like curved staircases, built-in furniture, and architectural elements that must integrate seamlessly with existing structures.

Sustainable Joinery Production Practices

Environmental responsibility plays an increasingly important role in modern joinery manufacturing. Antonovich Group implements sustainable practices throughout their production processes, including material optimization to minimize waste, dust collection systems for byproduct recycling, and partnerships with certified sustainable timber suppliers. The workshop's efficient material utilization processes maximize yield from each timber board, while offcut materials are repurposed for smaller components or accent pieces. This approach reduces waste while maintaining cost-effectiveness in luxury joinery production.

Project Coordination and Installation Support

Successful joinery projects require seamless coordination between workshop production and on-site installation teams. Antonovich Group's project management systems ensure that manufacturing schedules align with overall project timelines, accounting for finishing requirements, hardware mounting, and transportation logistics. Technical support during installation phases includes detailed assembly instructions, hardware specifications, and adjustment procedures that ensure proper fit and function. This comprehensive approach minimizes callbacks and ensures client satisfaction with completed installations.

Innovation in Traditional Craftsmanship

While respecting time-tested joinery techniques, Antonovich Group continues investing in technological advancement and process improvement. Recent innovations include automated material handling systems, improved dust collection efficiency, and enhanced finishing techniques that reduce environmental impact while maintaining superior quality standards. The combination of traditional craftsmanship skills with modern manufacturing technology positions Antonovich Group at the forefront of luxury joinery production, capable of executing projects ranging from intimate residential spaces to large-scale commercial installations with consistent excellence and attention to detail.

More projects

We will call you back!

Enter your contact details and our manager will contact you.