Metal works

Redefining Modern Interior Design Through Precision Metal Works

Contemporary interior design increasingly embraces the versatility and sophistication of metal elements, transforming spaces through sculptural forms, functional beauty, and industrial elegance. Antonovich Group has established itself as a leader in architectural metalwork, combining advanced fabrication techniques with innovative design concepts to create stunning metal installations that define modern luxury interiors.

Comprehensive Metal Fabrication Services

Antonovich Group's metalwork division offers complete fabrication services spanning from initial concept development to final installation. Their capabilities encompass precision cutting, welding, forming, and finishing of various metal alloys including stainless steel, aluminum, brass, copper, and specialty metals. This comprehensive approach ensures seamless integration of metal elements throughout interior spaces. The fabrication facility features state-of-the-art equipment including laser cutting systems, CNC plasma cutters, precision brake presses, and automated welding stations. These technologies enable the production of complex geometries and intricate patterns while maintaining consistent quality across both small decorative elements and large architectural installations.

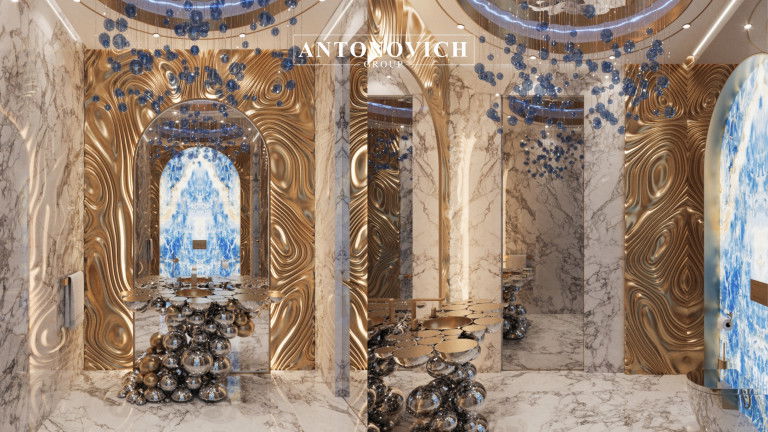

Stainless Steel Fabrication and Modern Applications

Stainless steel represents the cornerstone of contemporary metal interior design, offering durability, hygiene properties, and timeless aesthetic appeal. Antonovich Group specializes in various stainless steel grades and finishes, from mirror-polished surfaces to brushed textures and custom patina treatments that create unique visual effects. Kitchen applications showcase the versatility of stainless steel fabrication, including custom countertops, backsplash panels, and integrated appliance housings. The fabrication process involves precision measuring, template creation, and seamless welding techniques that eliminate visible joints and create smooth, easy-to-clean surfaces. Architectural stainless steel installations extend beyond functional applications to include decorative wall panels, room dividers, and sculptural elements. Advanced forming techniques allow for curved surfaces, compound angles, and complex three-dimensional shapes that push the boundaries of traditional metalwork.

Custom Aluminum Work and Lightweight Solutions

Aluminum fabrication offers exceptional design flexibility combined with lightweight properties ideal for suspended installations and large-scale architectural elements. Antonovich Group's aluminum capabilities include extrusion selection, custom cutting, welding, and various finishing options from anodizing to powder coating systems. Perforated aluminum panels create striking visual effects while providing functional benefits such as acoustic control and ventilation. The perforation patterns can be customized to create decorative designs, logos, or geometric patterns that serve as both functional and aesthetic elements within interior spaces. Aluminum framing systems for glass partitions and display installations require precision fabrication and specialized glazing techniques. The team utilizes structural glazing methods and weatherproof sealing systems that ensure long-term performance and maintenance-free operation.

Brass and Bronze Craftsmanship

Traditional brass and bronze work adds warmth and elegance to contemporary interior designs through rich patinas and handcrafted detailing. Antonovich Group's brass fabrication expertise includes both modern precision techniques and traditional hand-forging methods that create unique textural qualities. Custom brass fixtures, hardware, and decorative elements undergo specialized finishing processes including antiquing, buffing, and protective coating applications. These treatments enhance the natural beauty of brass while providing durability and resistance to tarnishing in interior environments. Bronze casting capabilities enable the production of artistic elements, custom hardware, and architectural details that cannot be achieved through conventional fabrication methods. The casting process involves pattern making, mold preparation, and precision finishing that results in museum-quality bronze installations.

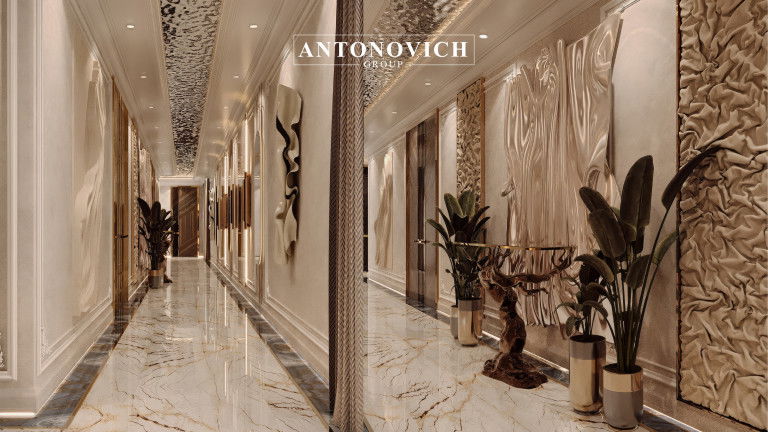

Architectural Metal Screens and Partitions

Metal screen installations serve dual functions as design elements and practical space dividers, offering privacy control while maintaining visual connectivity between areas. Antonovich Group designs and fabricates custom metal screens using various materials and perforation patterns tailored to specific aesthetic and functional requirements. Laser-cut metal screens showcase intricate patterns and designs that would be impossible to achieve through conventional fabrication methods. The precision of laser cutting enables fine detail work, complex geometries, and consistent pattern repetition across large installations. Installation of metal screen systems requires careful planning for structural support, mounting hardware, and accessibility for maintenance. The team utilizes concealed fastening systems and adjustable mounting brackets that accommodate building movement while maintaining screen alignment.

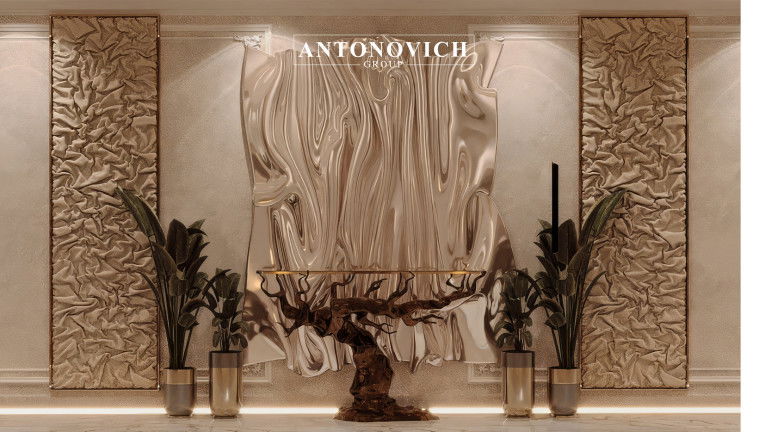

Decorative Metal Cladding and Wall Systems

Metal wall cladding transforms interior surfaces through texture, color, and reflective properties that enhance spatial perception and lighting effects. Antonovich Group's cladding capabilities include various metal types, surface treatments, and installation methods suitable for both residential and commercial applications. Corrugated metal panels, expanded metal sheets, and custom-formed cladding elements create dynamic wall surfaces that interact with lighting to produce ever-changing visual effects throughout the day. The selection of appropriate metal gauges and support systems ensures structural integrity while minimizing installation complexity. Integrated lighting within metal cladding systems creates dramatic backlighting effects and accent illumination. The coordination of electrical rough-in with cladding installation requires careful planning and specialized mounting details that conceal wiring while providing easy access for maintenance.

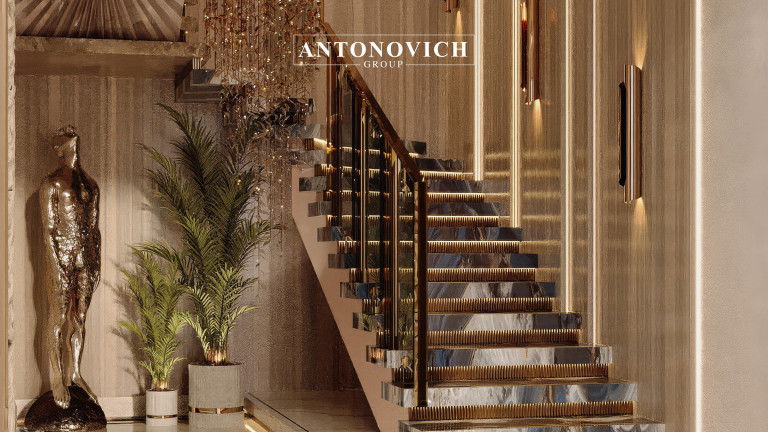

Custom Staircases and Railings

Metal staircase fabrication represents one of the most technically demanding aspects of architectural metalwork, combining structural engineering with aesthetic design requirements. Antonovich Group's staircase capabilities encompass floating stairs, spiral configurations, and custom railing systems that serve as sculptural focal points within interior spaces. Structural calculations for metal staircases must account for code requirements, load distributions, and connection details to existing building structures. The fabrication process involves precision cutting of stringers, treads, and risers with careful attention to dimensional accuracy and welding quality. Railing systems integrate safety requirements with design aesthetics through custom baluster patterns, handrail profiles, and connection details. Various infill options including glass panels, metal screens, and cable systems offer different levels of transparency and visual weight within the overall staircase design.

Precision Welding and Joining Techniques

The quality of metal fabrication depends heavily on welding expertise and joining techniques that create strong, durable, and visually appealing connections. Antonovich Group's welding specialists are certified in various processes including TIG welding, MIG welding, and specialized techniques for different metal combinations. Invisible welding techniques create seamless joints that maintain clean lines and smooth surfaces essential for high-end interior applications. Post-welding finishing processes including grinding, polishing, and surface preparation ensure that welded connections are indistinguishable from base materials. Quality control procedures for welded assemblies include visual inspection, dimensional verification, and structural testing where required by application or building codes. This systematic approach ensures that completed metalwork meets both aesthetic and performance standards.

Surface Finishing and Protective Treatments

Surface finishing represents the final critical step in metal fabrication, determining both appearance and long-term durability of completed installations. Antonovich Group offers comprehensive finishing services including mechanical polishing, chemical treatments, and applied coating systems. Brushed finishes create consistent directional patterns that minimize fingerprint visibility while maintaining the natural beauty of metal surfaces. The brushing process requires specialized equipment and techniques to achieve uniform appearance across large surfaces and complex geometries. Patina treatments and oxidation processes can create unique color variations and textural effects on copper, brass, and steel surfaces. These treatments require careful control of environmental conditions and chemical applications to achieve consistent results and prevent unwanted corrosion.

Integration with Modern Technology

Advanced metal fabrication increasingly incorporates digital design tools, automated processing equipment, and precision measurement systems that improve accuracy while reducing production time. Antonovich Group utilizes CAD/CAM integration that translates design concepts directly into fabrication instructions for CNC equipment. 3D modeling capabilities enable detailed visualization of complex metalwork installations before fabrication begins, allowing for design refinement and clash detection with other building systems. This technology reduces field modifications and ensures proper fit-up during installation phases. Robotic welding systems provide consistent quality and increased production capacity for repetitive fabrication tasks, while maintaining the flexibility for custom work that requires skilled craftsman techniques.

Project Coordination and Installation Excellence

Successful metalwork projects require careful coordination with other trades and building systems to ensure proper sequencing and interface details. Antonovich Group's project management approach includes detailed shop drawings, material scheduling, and coordination meetings that minimize conflicts and delays. Installation teams utilize specialized rigging equipment, temporary support systems, and precision alignment tools appropriate for heavy metalwork installations. Safety procedures include fall protection, lifting protocols, and jobsite coordination that protects workers while maintaining installation quality and schedule adherence.

More projects

We will call you back!

Enter your contact details and our manager will contact you.